Boat Flooring Information

U-DEK® marine decking is a great looking and high performing option for all types of marine craft from wake and ski boats, fishing boats,houseboats, pleasure cruisers, motor yachts, to RIBS and personal watercraft. U-DEK® is proven in the harsh marine environments and perfect for other applications such as caravans, trailers, golf carts & automotive, commercial and DIY projects.

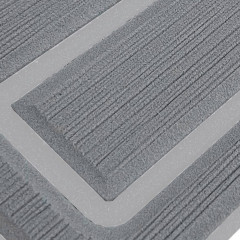

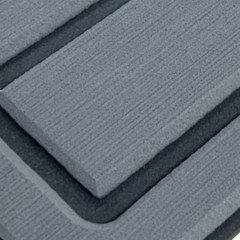

It is made from lightweight closed cell foam, offering a high level of comfort underfoot and excellent traction in all conditions. Durable, low maintenance, U-DEK® has been designed specifically for deck kits and is supplied in various colours and tread options to suit individual styles.

As a leading global manufacturer of PE and EVA foam, Ultralon Foam International designs and produces U-DEK® using our own dedicated plant and IP. Tightly controlled manufacturing processes, careful selection of raw materials, high level technical expertise and the latest technology and equipment, enable us to offer customers quality, reliability and consistency of product.

Experience the benefits of U-DEK®:

Easy to clean to keep it looking fresh day after day. Low maintenance decking solution – minimum effort for maximum enjoyment. Good underfoot comfort for long days on the water. Great traction in all weather conditions. Custom routing to create unique designs. Durable solution that is proven to last upwards of 8 years. Lightweight foam with proven performance.

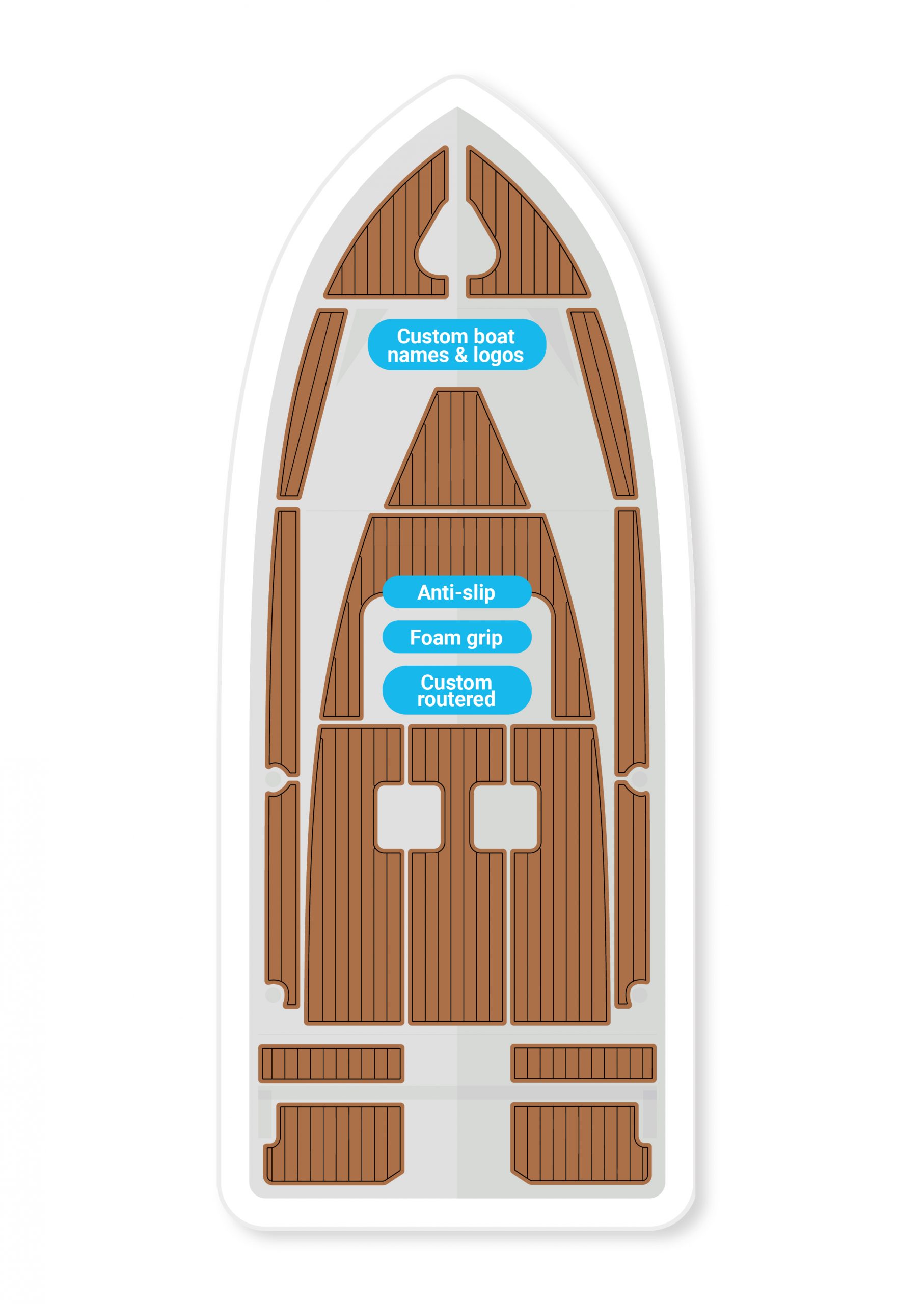

‘Tailored to you and your craft’

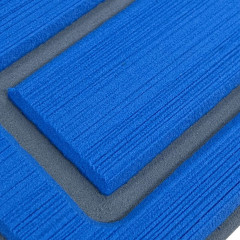

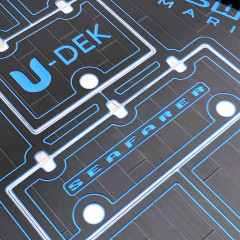

We measure to fit your boat’s exact specifications and design to work with all unique aspects of the floor. Include the manufacturer logo, or your own custom design to CNC cut into the U-DEK foam.

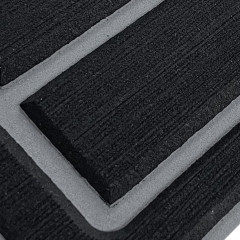

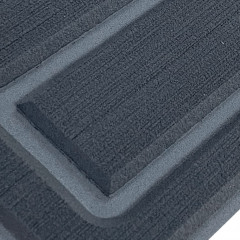

DUAL LAMINATED STANDARD COLOUR

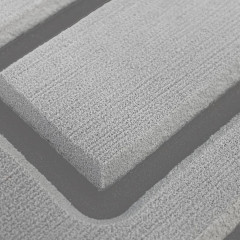

LAMINATED COLOUR

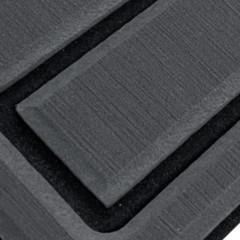

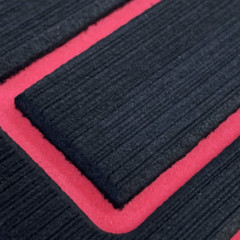

ROUTING OPTIONS

Offering a traditional teak-look, without the investment or ongoing maintenance, U-DEK Custom Routered provides excellent protection for your boat, whilst looking good and being comfortable under foot. The panels and custom patterns are achieved by CNC routering the top layer of foam, exposing the layer underneath, with bevelled edges to ensure a high-quality finish.